MrResin

Resin Pro Transparent Epoxy

Resin Pro Transparent Epoxy

Couldn't load pickup availability

TRANSPARENT EPOXY RESIN

Water Effect – Two-component epoxy system with high performance for film application (1mm) and castings up to 2cm thickness.

Besides the high transparency (water effect) and the self-levelling properties, it guarantees a good mechanical seal for reinforcement and applications with carbon fibre.

The product is characterised by a low viscosity that reduces the presence of air bubbles after hardening and facilitates the impregnation of carbon fibre.

The excellent resistance to environmental humidity guarantees a glossy and transparent surface.

The product is compatible with the main colouring pigments and mica.

Transparent Epoxy resin is a two-component product based on epoxy resins and relative amino hardener.

The main features of this product are:

- high transparency,

- excellent mechanical strength,

- good chemical resistance,

- high impregnation and reinforcement of technical fabrics,

- long work ability,

- glossy and self-levelling surface.

The product can be coloured with any epoxy dye (both in paste and powder) in a percentage ranging from 0.1% to 2.0%).

These characteristics make the transparent epoxy resin ideal for the following applications:

- Modeling;

- Artistic creations;

- Fiberglass repairs;

- Outdoor protective coatings;

- Artistic flooring;

- Sailing;

- Impregnation of technical fabrics (fiberglass, carbon fiber, Kevlar).

Pot-life (150 gr to 30 C): 1h20m ′, Catalysis complete after 24h,

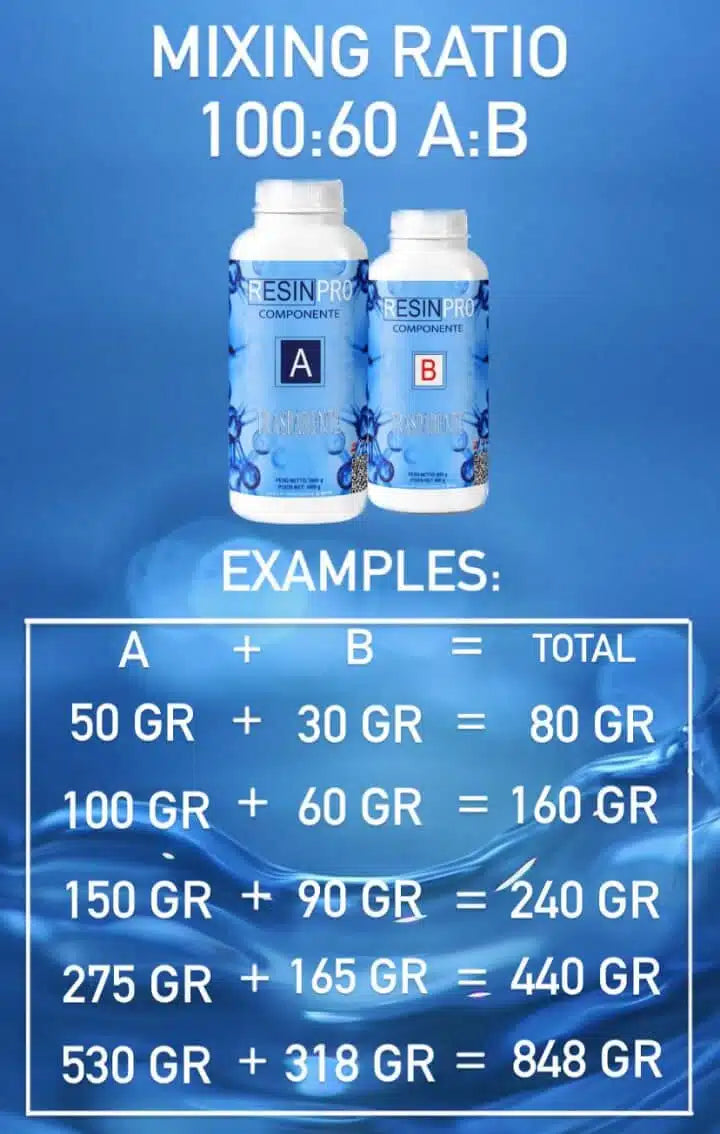

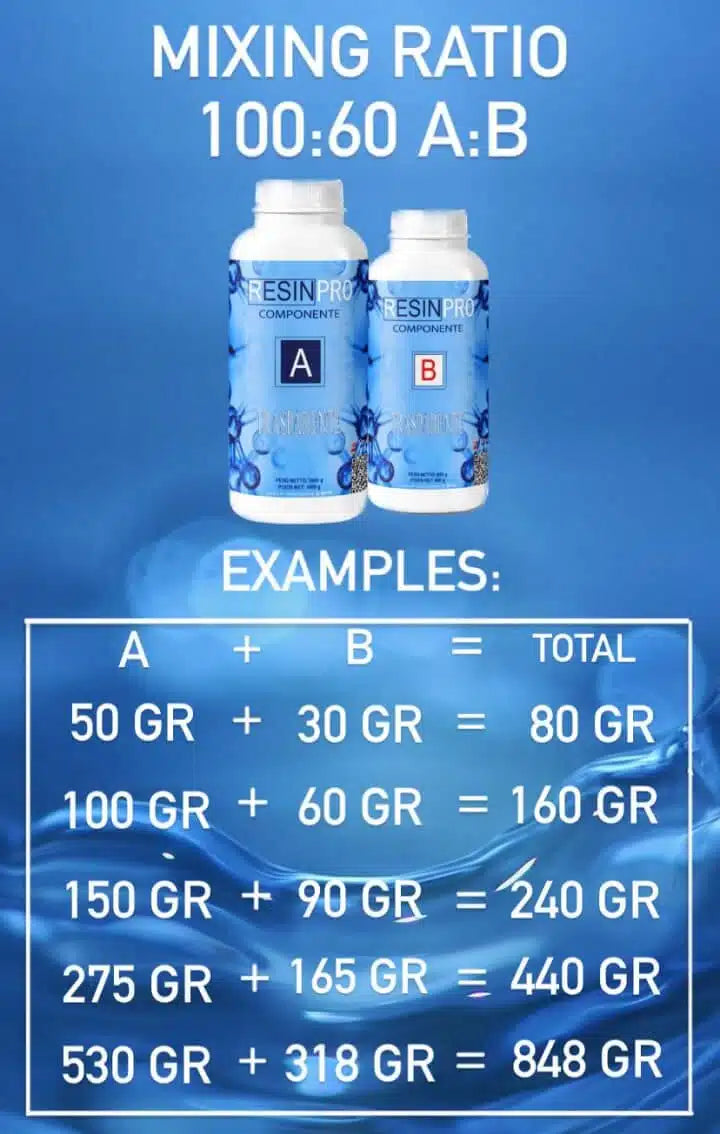

How to use. Mixing ratio based on weight – 100:60.

For best results, measure two components based on weight using a scale within 5% of the recommended mixing ratio.

• Always mix the product thoroughly for at least 2 minutes, scraping all surfaces in the container to ensure complete mixing.

• Try to use the product in a temperature-controlled environment within the optimal product specifications.

• Avoid high humidity or cold ambient temperatures.

• For optimum bonding performance, make sure the surface is dry and free of dirt, debris and oils. Mechanical preparation the sanding surface is highly recommended.

• Perform small preliminary tests to fully understand the polymerisation characteristics of the resins in your work environment and compatibility of the resins with other materials.