MrResin

The SoliMould Range

The SoliMould Range

Couldn't load pickup availability

Introducing the new SoliMould

The difference between these moulds and others really is Black and White.

Milled from solid HDPE blocks means no seams or joints that can leak, they are hard-wearing and will not deteriorate from multiple uses with resin.

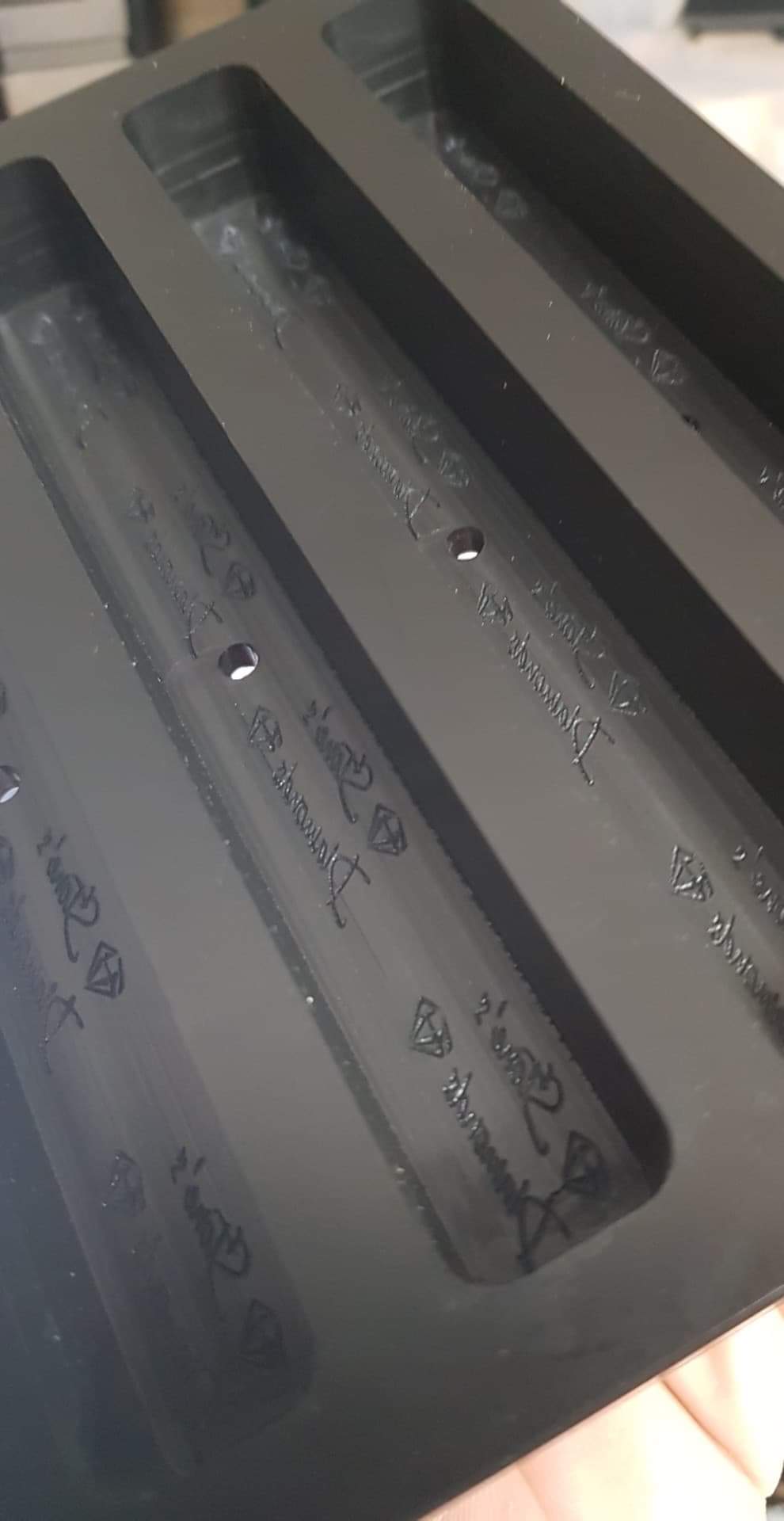

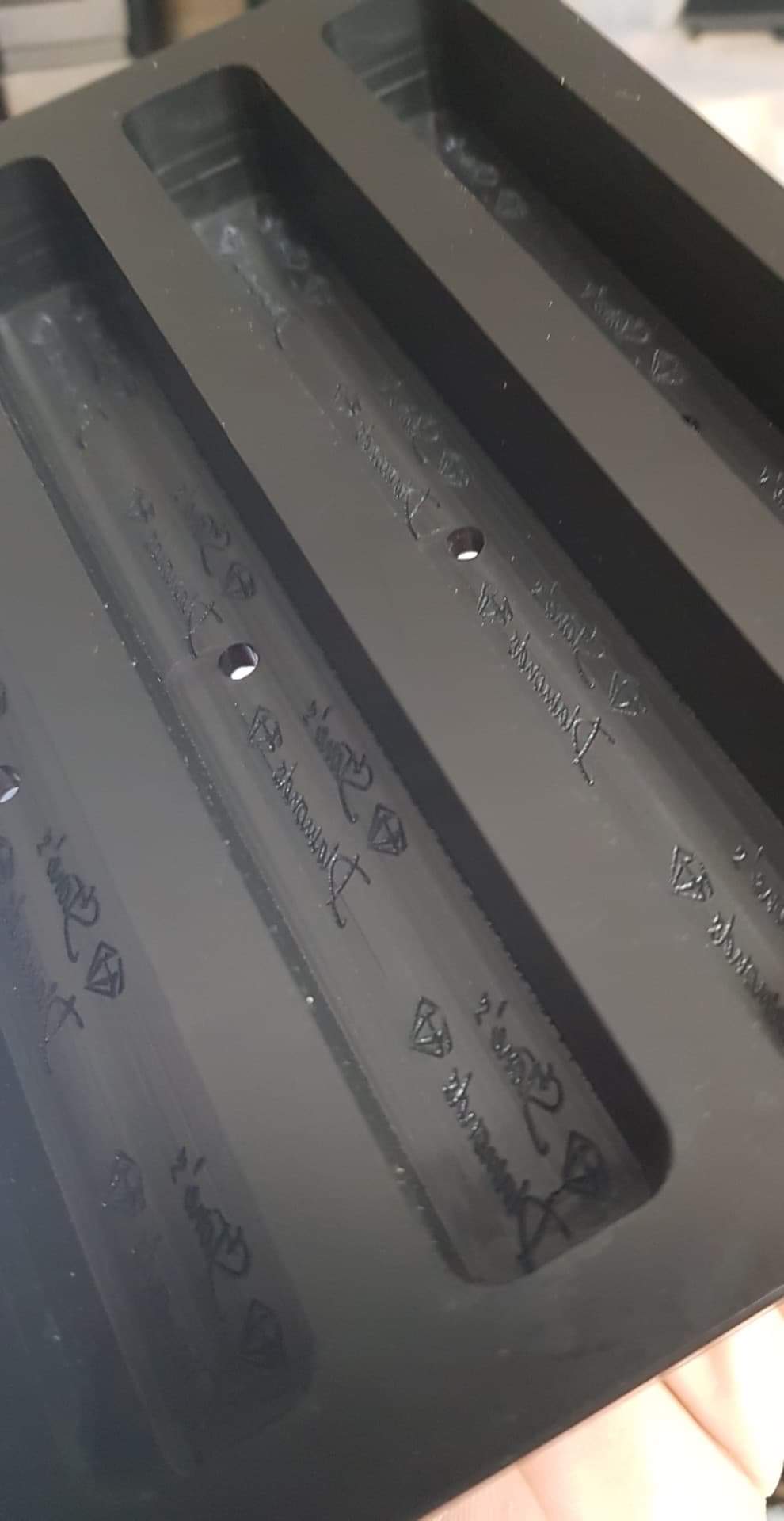

Each cavity in the Solimould Quad is 20 x 20 x 150mm the XL being 20x20x200mm with a very slight taper on the sides to ease removal. This taper is around 0.25mm and not as much as some others may have you believe. Also in tests we found the Solimould to use less resin than most other brands on the market and even less that many of the dedicated silicone moulds when casting sierra blanks.

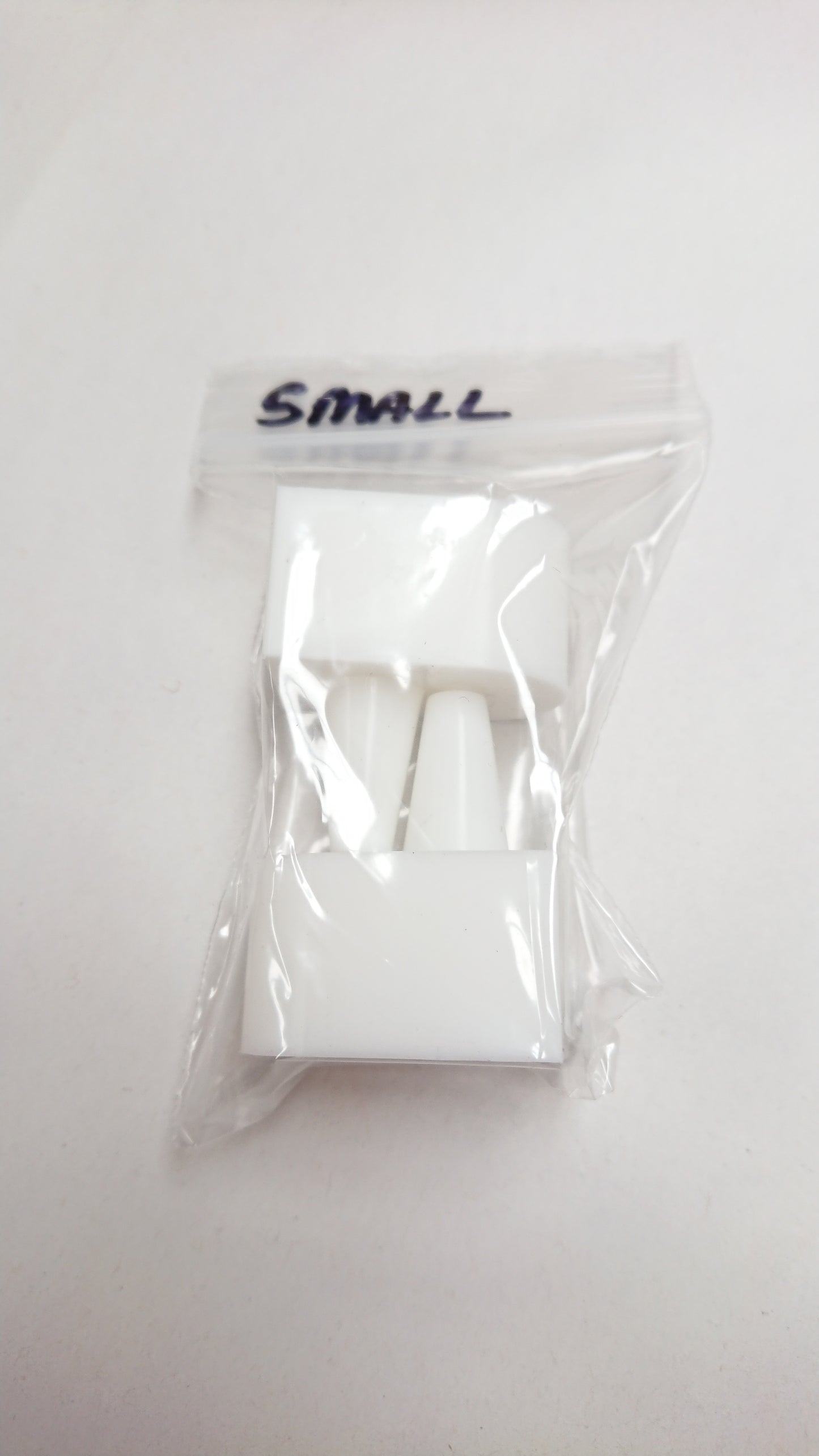

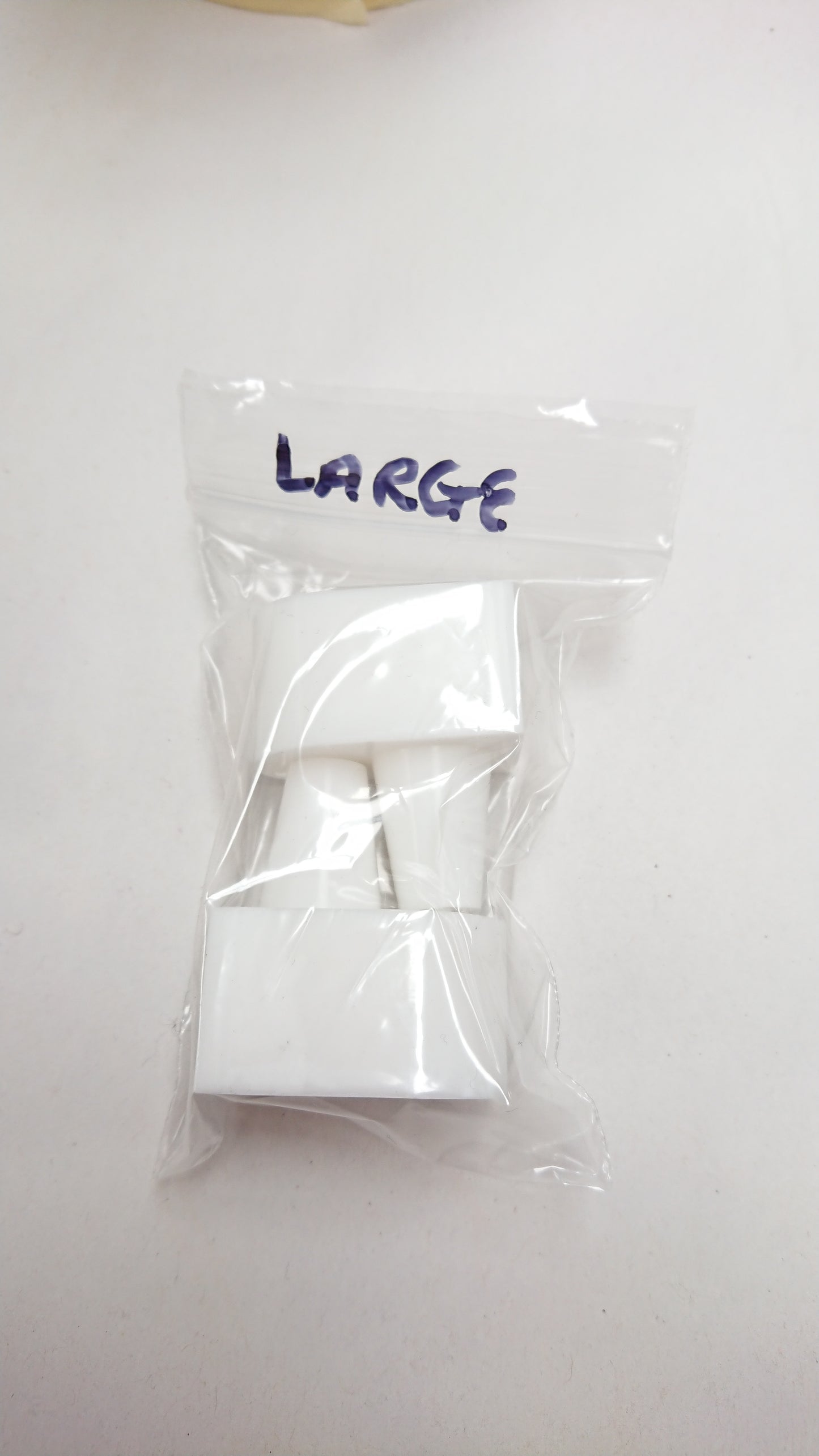

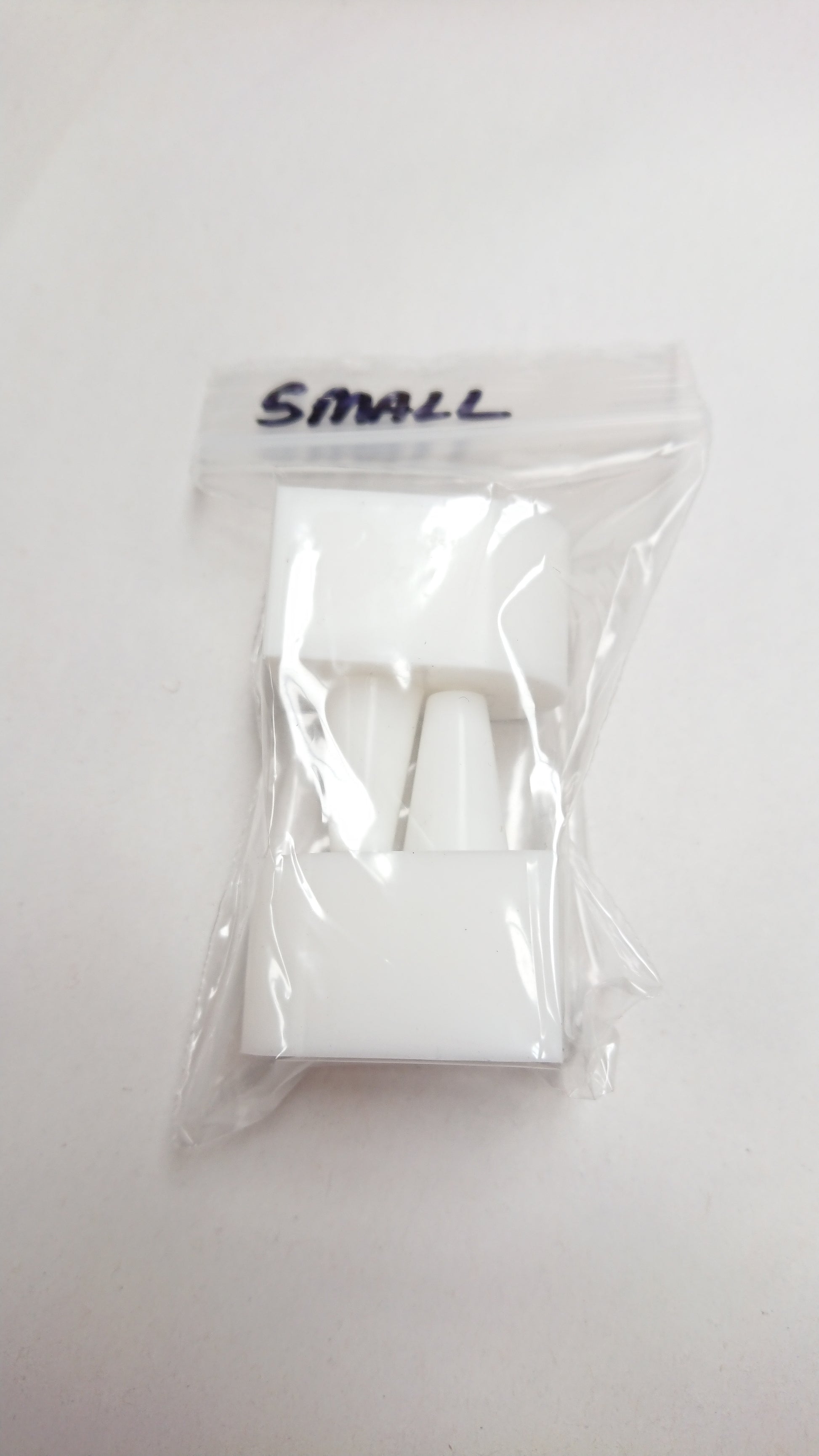

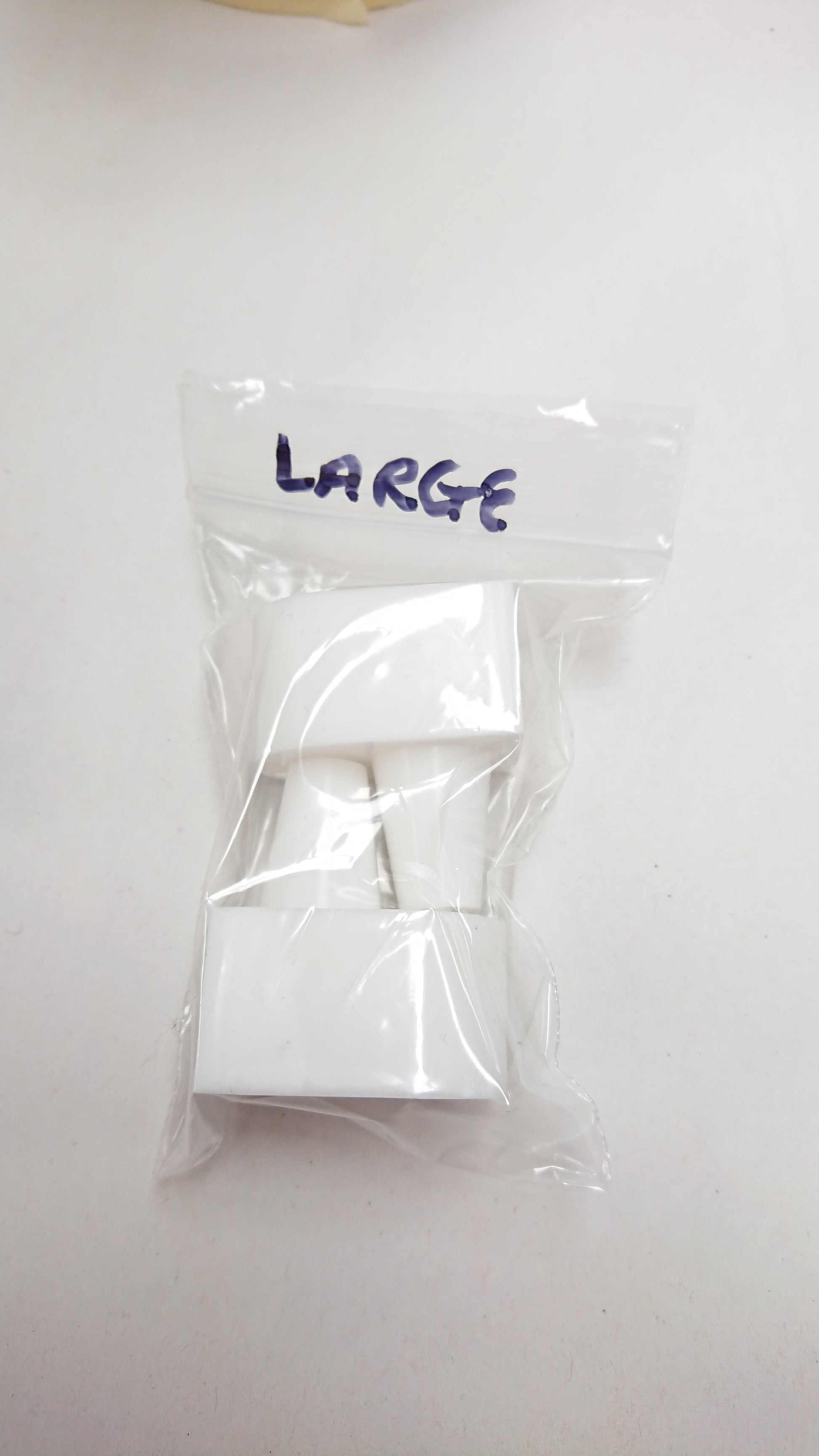

The Quad includes a set of 4 large and 4 small bungs to allow for tube in casting. YES the bungs are included, we do not charge extra for the first set. These bungs will allow for a range of kits from slimline up to most 2 part cap tubes (max 14mm). With 4 cavities this means you can cast for 2 complete 2 part kits or 4 single barrel kits. If you wish it is also possible to cast pen blanks and tube in casts in the same mould. Because of the length of cavity in the SoliMould even razor handles and long tube pen kits are easily accommodated.

The new Quad XL includes 2 sets of bungs that come with the normal Quad. This means you get 8 large bungs and 8 small bungs. The cavity on the XL is 200mm long so long enough for most 2 part pen kits cap and nib sections and plenty for 8 sierra tubes or many other single tube kits. Also at 200mm long long enough for kitless blanks to be cast. Although longer than many others on the market the Solimould XL has been made to still fit in a standard 10litre pressure pot.

*Please note the colour of the bottom bungs may vary*

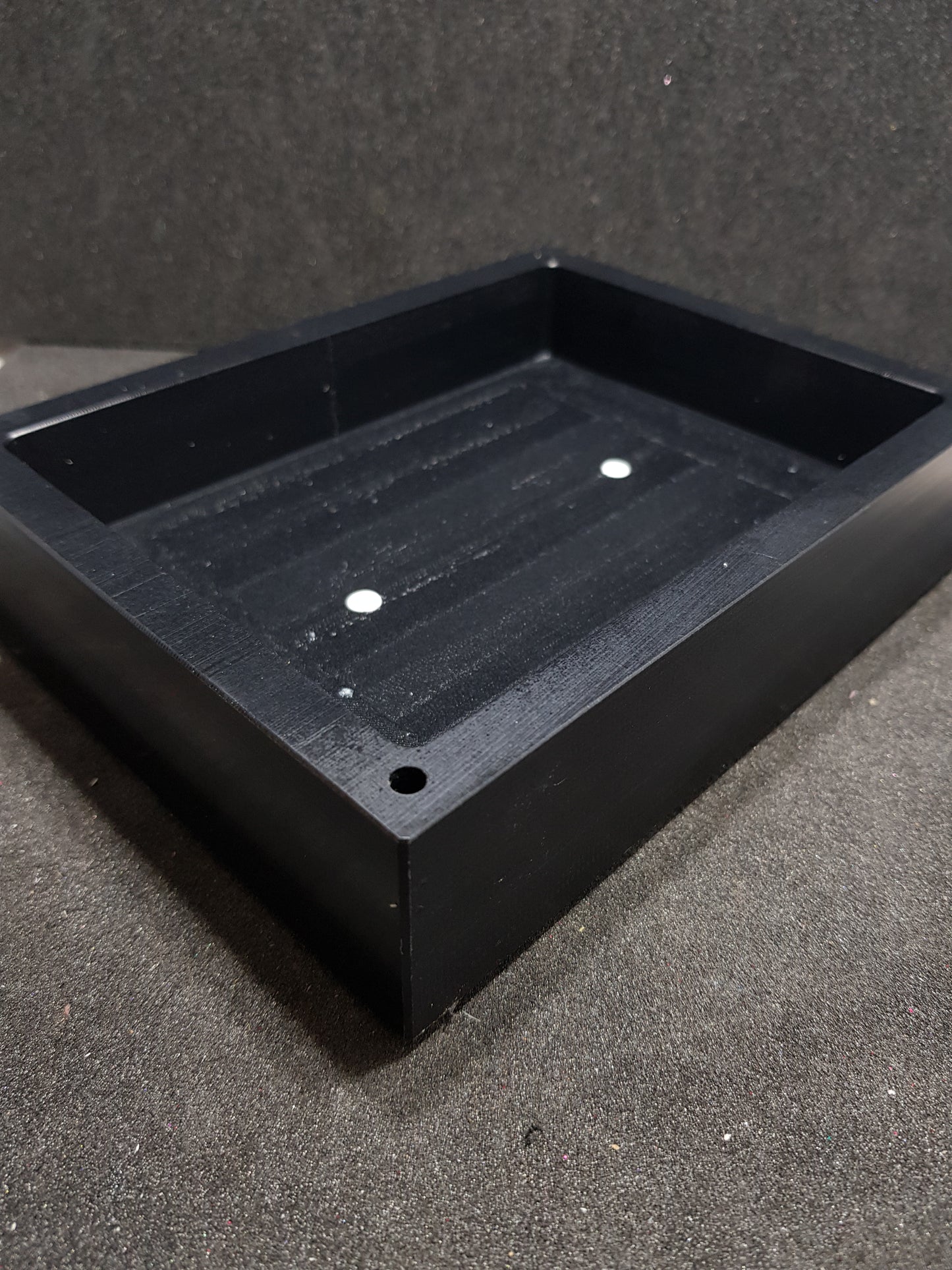

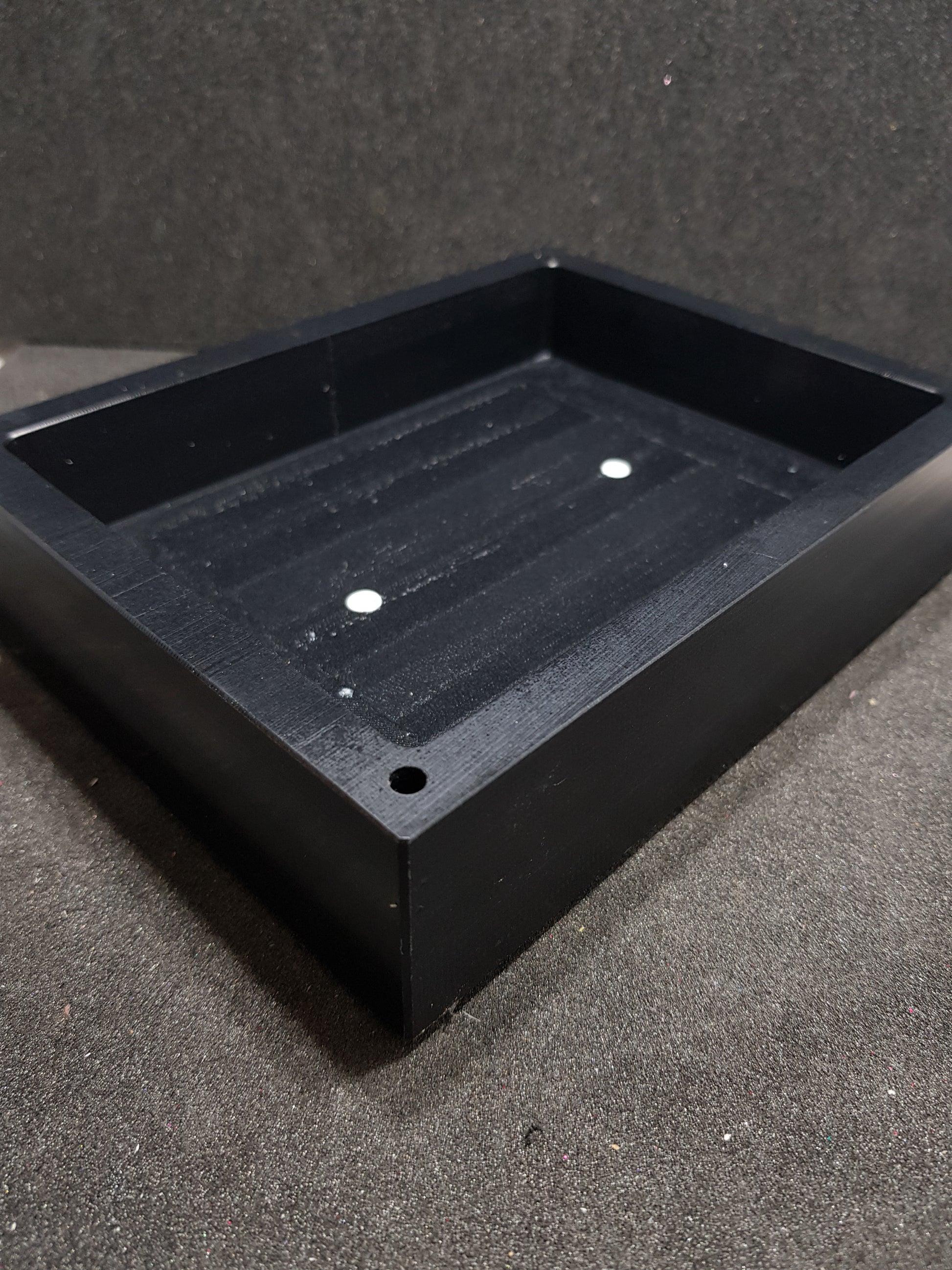

The Solimould Slab has a cavity of 150 x 110 x 25mm this allows for a great number of uses. Many use for slab casting pen blanks and depending on the size of blanks you prefer you can get quite a few out of this mould.

The Solimould Double has been designed to make 2 knife scales. The cavities are 150x50x25mm. This also means that you can get 2 pen blanks out of each casting if you prefer.

These come with bungs fitted to the bottom to allow de-moulding using an air blower, or alternatively a light tap with a punch through the hole.

We use a dead blow hammer on the back of our moulds to release blanks and this works very well.

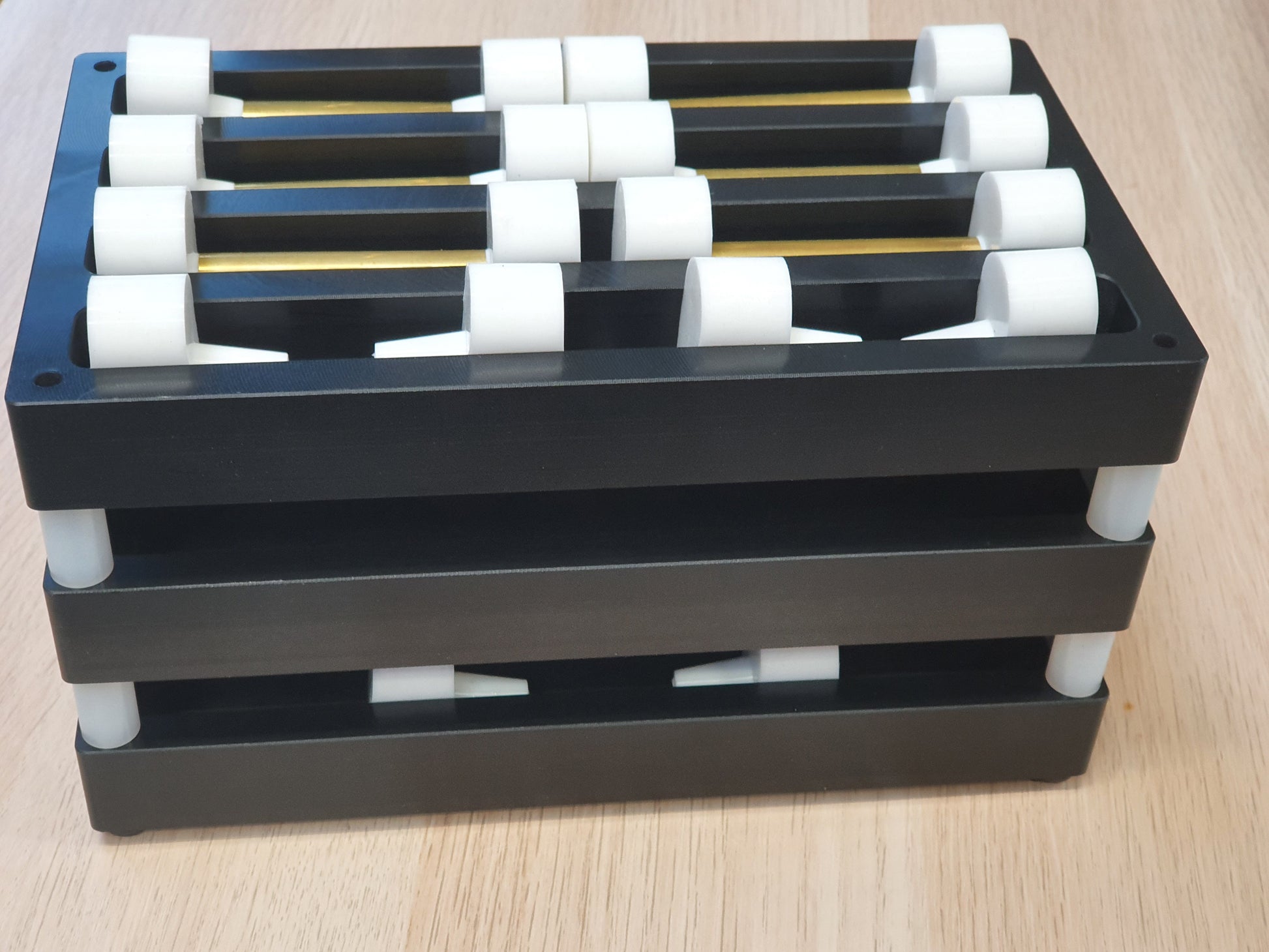

The new SoliMould stack parts allow the SoliMould range to be stacked in a tower formation. This removes the need of pressure pot caddys and helps to save space in the pressure pot.

It is advised that a release agent is used with this product to ease in the de-moulding procedure, a silicone spray can be found on our website. We have always used silicone release spray and have had no issues with any of our own moulds, solimould or any choice of resin used.

Below is a video review on the Solimould....

The cavity of the SoliMould is plain bottomed. This can be marked with your company name if you sell blanks. This is handy for people to know exactly where they bought the blank when they want to re-order.

The SoliMould brand name is not engraved in the cavities this was only done on the early sample moulds sent to demonstrators.